Application industries: This carton opener has been widely used in food, medicine, beverages, tobacco, daily chemicals, electronics and other industries.

| project | parameter |

| Unboxing ability | 12 boxes/minute |

| Carton temporary inventory | 100pcs(1000mm) |

| Carton size | L:250-450 W:150-400 H:100-400mm (small sizes cannot exist together) |

| use electricity | 220V 1ф 200W |

| necessary air pressure | 6kg/cm² |

| air consumption | 450 NL/min |

| Machine size | L2000×W1900×H1450mm |

| Tape size | 48、60、75mm |

| Mechanical weight | 450kg |

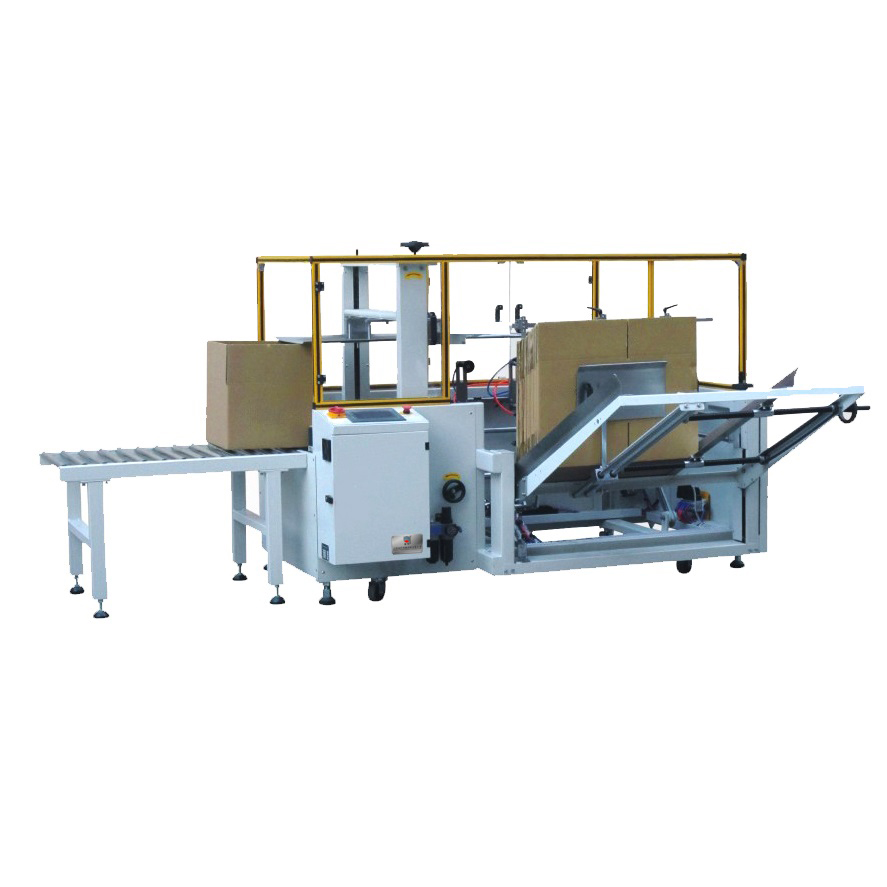

1. The automatic carton forming machine is manufactured with independent technology and uses imported parts, electrical components and pneumatic components; it adopts a vertical storage method of cardboard and can replenish carton boards at any time without stopping the machine.

2. The back sealing machine is rationally designed, absorbs and forms simultaneously, and folds the bottom and the back cover are formed simultaneously at one time; it is light in size, precise and durable in mechanical performance, has no vibration in the operation process, is stable in operation, has a long lifespan, and is highly efficient.

3. Suitable for packaging of the same carton size at the same time. If you need to change the carton size, you can adjust it manually. It takes 1-2 minutes.

4. Install a transparent plexiglass protective cover, and the door will automatically stop to avoid accidental operations.

5. It can be operated as a stand-alone machine or used in conjunction with automated packaging lines.

Shanghai Shengzhe Mechanical Technology Co., Ltd. was founded in 2003 and is a professional manufacturer integrating production, engineering, and trade. After 10 years of forging, it has gradually formed packaging equipment with pharmaceuticals, food, cosmetics, and other products as its main products: high-speed cartoning machines, transparent film three-dimensional packaging machines, transparent film bundling machines, integrated box opening, packing, and sealing machines, fully automatic unmanned bundling machines, as well as multifunctional pillow-type packaging machines, labeling machines, wrapping machines, wrapping machines, filling and sealing machines, extrusion sheet machines, paper bowl machines, bowl sticking machines, disc box machines, capping machines, cup stacking machines, molds, and other diverse series of electromechanical fully automated machinery and equipment.